Hicks "Special" Cars

Here is the complete text from a 1908 Hicks promotional book about Hicks

Gasoline-Electric Motor Cars:

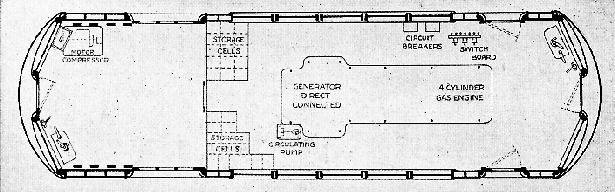

“THE TYPE of gasoline-electric motor cars built by the Hicks

Locomotive & Car Company has proven an unqualified success through two years

of constant service. The car described and illustrated herein is 35 feet long

and has two compartments, engine room and baggage room, but cars may be of any

length and include passenger compartments, if desired.”

“THE FRAMING is composite, steel and wood, designed especially

to withstand severe strains and to eliminate vibration and noise.”

“THE MOTIVE POWER is derived from a four-cylinder gasoline

engine in combination with a Sprague Electric Company direct-connected

generator. This engine developed under factory tests 70 dynamometric h.p. at

325 r.p.m., with a consumption of one pint of gasoline per h.p. hour. The

cylinder jacket water is kept in constant circulation through a system of

pipes and supply tanks by means of a rotary pump. The radiation of heat is

rendered more effective by two large fans exhausting through roof ventilators.

The engine is fed with gasoline by a reciprocating pump, from a tank

underneath the car, the supply to the engine always being greater than

required, and the excess gravitating back into the reservoir. The gas engine

is started by operating the generator as a motor, current being supplied by

the storage battery. In emergency cases, compressed air may be used for this

purpose.”

[Text continues below

images.]

|

|

This is the Hicks

Gasoline-Electric Motor Car. Click image above for enlargement. |

“ELECTRIC TRANSMISSION — The engine is direct-connected to a

50 k.w. 250-volt generator, in parallel with which is connected a storage

battery consisting of 120 cells of ‘Chloride Accumulator’ type 11-ECS,

manufactured by The Electric Storage Battery Co.”

“The power demand of the motors varies through a wide range,

from zero while the car is at rest to a maximum during acceleration. The

combination of generator and battery is so designed as to automatically

maintain a practically constant power output from the generator. The battery

receives power from the generator when the motor demand is light, and gives

out power at times of heavy motor demand, the output of the generator thus

remaining practically constant.”

“The system as outlined, by relieving the generating unit of

heavy variations of load, insures ideal engine operation, materially reduces

the wear and minimizes the chances of a breakdown in this unit.”

“The battery also serves as an important reserve. On this car

the battery alone supplied the entire power for propelling it from one end of

its run to the other, a distance of 10 miles. In the event of a breakdown of

any of the engine or generator parts, the battery eliminates the possibility

of a train being stalled between stations.”

“The leads for the battery and the generator are carried to a

switchboard of special design, and connected in multiple to the main

controller leads. Circuit breakers, capable of adjustment for a series of

amperages, are connected in the battery and generator leads to the

switchboard, to obviate the necessity of replacing blown-out fuses.”

[Text continues below

images.]

|

Above: interior view of

the Hicks Gasoline-Electric Motor Car. Below: floor plan of the car. Click image below for enlargement. |

|

“OPERATING CONDITIONS — A complete test was

recently made and the accompanying curves illustrate the output of the

generator, the input and output of the battery and the input to the motors,

during a run of the car from one end of the line to the other. It will be

noted from these curves that the demand of the motors at one time varied from

0 to about 60 k.w., or 80 h.p., in a very few seconds. If it were not for the

battery, this severe fluctuation would have fallen on the gasoline engine. The

curves clearly illustrate the practically constant load that is maintained on

the engine.”

“During the test the train consisted of a motor car weighing

35 tons and a 19-ton trailer. In the normal operation of the road, three round

trips a day are made with this train. On special occasions, such as holidays,

a more frequent schedule is maintained and additional trailers are used, the

motor car having pulled as many as three loaded trailers over the line. Under

normal operating conditions, namely, three round trips a day, this car

operates on about 30 gallons of gasoline per day.”

“The generator also supplies current for light, for gas engine

ignition and for a 4 h.p. motor compressor for the air brake system.”

“When necessary the cylinder heads and pistons may be removed

through the ventilating doors in the roof.”

“The total weight of this car is approximately 70,000 lbs.”

[End text.]

|

|

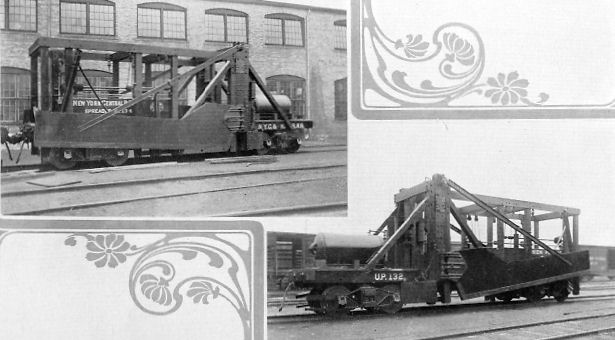

Spreader cars built for

the O.F. Jordan Company about 1907. |

Other Hicks pages (lots of images - may take several minutes

to load) —