Work Weekend of Rivet Holes and Back Plate

Mike Wahl reports:

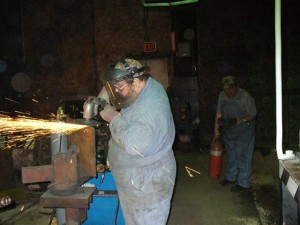

“It was another great weekend in the shop. This was weekend Four in a row. Great progress has been made since Snow Train. There were many people in the shop throughout the weekend.

“The number one priority for the weekend was to finish the rivet holes between the barrel courses. Jim Connors started with a crew on Friday boring holes. On Friday, Jim, Doug Klitzkie, and Bryon Schumacher completed the second course. This work continued Saturday with the same crew working on the first course. We worked late into the evening to complete the boring but when we quit on Saturday the holes were all bored.

“The second priority was to make a new backer plate for the throat sheet. This work started on Friday evening with Pete Deets and Tennessee cutting the piece of material. On Saturday Pete, Mike Flood, Jim Gaiser, and Ed Ripp continued work on this. By the end of the day the backer was fitted and the rivet holes were drilled.

“While this transpired, Al Joyce and Dave Wantz were busy in the machine shop making studs for the throat sheet.

“On Saturday Mike Flood and I went out and measured up the tender. With the nice weather we were able to spend a good deal of time looking the tender over and also looking at how the 22’s tender was repaired. From this information a repair plan and drawings will be completed.

“Chris completed seal welding smokebox seams. There is a little welding left to complete on the front ring and a few bolt holes to weld-up that are misplaced.

“Saturday we were able to complete another task on the list. Ron Kokemuller was able to loan an auto feed magnetic drill to complete the boring of all 196 tube holes. Ron thank you for finding this equipment, it has sure made short work of the tube holes.

“On Saturday Jeff Bloohm and Kelly Bauman gave me a hand measuring the driver tires and lead truck wheels.

“On Sunday the work on the backer plate continued with Doug Crary drilling the pilot holes in the sheet for the staybolts and marking the centers of the holes for the backers. When I left on Sunday he was busy drilling the clearance holes for the staybolts and the stud holes for tapping. Doug how far did you get?

“Doug and I also went on a scouting mission looking for the inlet check so a new mounting plate to the boiler can be designed. After some looking we have found it.

“Bryon and Ed on Sunday worked on tightening the course seam bolts. The third course is tightened up. We need to finish the second and first.

“As you can see it was a great weekend with the highlight being Jim Busse and his family putting together a cook-out on Saturday night. It was beautiful evening and great food. Thanks to Jim and his family.

“Thanks to all!”

Pete Deets adds:

“At one point in time we had three magnetic base drills working at the same time. One was the demonstration machine obtained & operated by Ron K. drilling the front tubesheet. The second was the Fein drill inside the boiler barrel that Jim C. and company were using to core rivet holes. The third machine was the BIG drill on loan from Jim Baker that Ed, Goz and I were using to drill the rivet holes in the throat sheet backer plate. With the stud work, welding on the smokebox and work on coach 425 going on at the same time it was a real happening place! Smoke, metal chips and excitement were in the air.”

Jim Connor photos.