Written by Mike Wahl

For this installment I will start with the history we have gathered about the original 1385 tender.

The original Chicago & North Western builder’s specifications from March of 1907 call out the following specs for the tender. I have summarized part of the information below.

Frame: The frame is to be substantially built of 13 inch steel channels and thoroughly braced.

Truck, Wheels, and Axles: The tender will carry two 4 wheel trucks. It was to have 5 1/2 x 10 inch journals with 33 inch wheels.

Tank: The tank is to have a capacity of 7500 gallons of water and 10 tons of coal. It is to be made of steel ¼ inch in thickness.

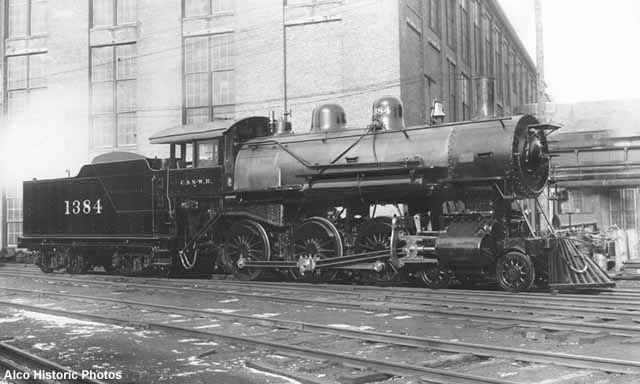

Included below is a picture of the 1384 which shows what the tender of the 1385 looked like in March 1907 when completed by the American Locomotive Company’s Schenectady Works.

The Chicago & North Western kept valuation records on all of their equipment. Each locomotive and tender was assigned a number to keep track of the cost spent on the equipment. The valuation record number for the locomotive was the locomotive number, the 1385 was 1385. The tenders were given a unique number. In the case of the 1385, tender number 7303 was with the locomotive when purchased by MCRM.

Using this record we can tell a few things about tender. On 10-19-1926 the tender received a cast steal frame, replacing the original steel channel frame, for a cost of $235.73. This is the first entry on the valuation record. It also states that the only engine it was in operation with was the 1385. So we do know that from 10-19-1926 until it retirement this was the tender the 1385 used. At this point we can only speculate that this was the tender it used from 1907 until 1926.

If you examine the photo of the 1384’s tender verses the tender photo’s of the 1385 I have included you can see some differences in the coal pocket area. The R-1 class locomotives with 7500 gallon tanks had a tender modification done, to add more coal capacity. They added radius wings to the edges and height to the front board to increase the tender’s capacity. There is a drawing called Tender Tank – Alteration for increased coal capacity date March 7th, 1944 that shows this change.

The Tender Plan

As I stated previously, the tender will be broken down into smaller tasks. They are the tank, tender frame and tender trucks.

Tank: The plan for the tender tank is to engineer and design a new welded tender tank to replace the original. The current tank will be used for reference along with the original drawing in the design of the new tank. The design goal of the new tank is to preserve a look as historically accurate as possible with the utilization of modern materials and manufacturing processes. To make this a restoration, not a completely new tank, we plan to use as much of the original hardware as possible like the coal board brackets, hatch parts and any other components that are salvageable.

Tender Frame: The tender tank was removed from the frame a few weeks back which allowed for us to perform an inspection. The overall condition of the frame was good. The contractor has removed the components from the frame, sandblasted it and it is in red oxide primer. The next step on the frame will be to examine it after cleaning and priming to determine what repairs are needed. I have included a picture of the frame taken by our contractor.

Tender Trucks: The tender trucks are in very bad condition. When the tender was parked at the end if the line at Quartzite Lake the trucks were buried in dirt and gravel. The team is currently evaluating rebuilding using roller bearing replacements as an option for the trucks. This decision will be made down the road once all of the options are evaluated.