August has arrived and with it is a new update on 1385’s boiler as it progresses toward becoming a finished vessel.

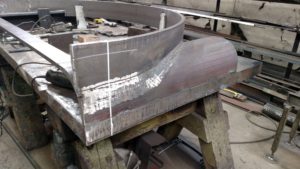

The fire door ring has been fitted to the firebox and backhead sheets and will be welded in place. The firemans’ shovel will pass through this opening many, many times feeding the fire that will keep 1385 running.

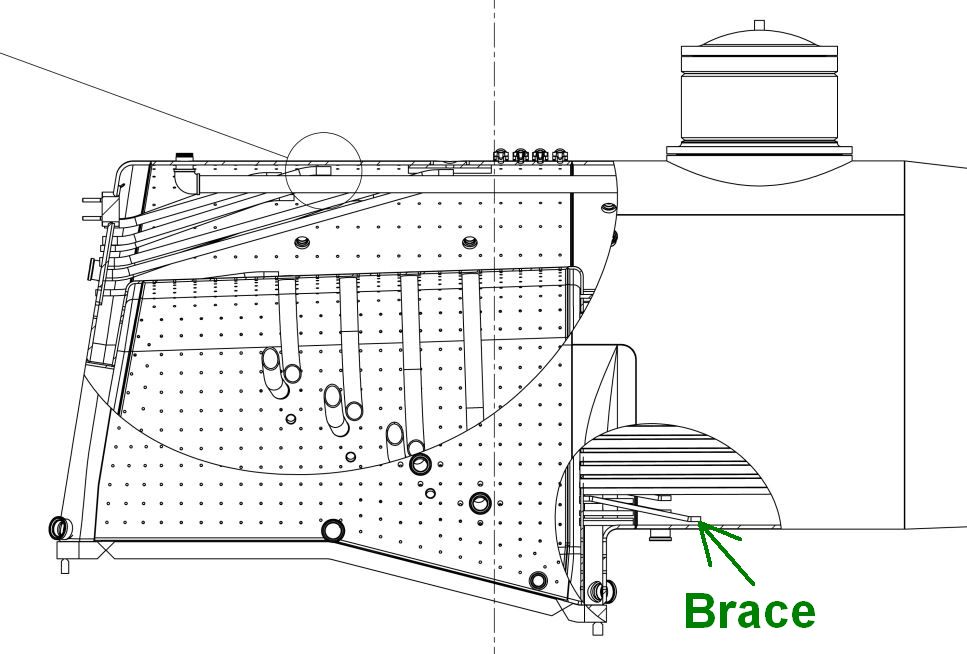

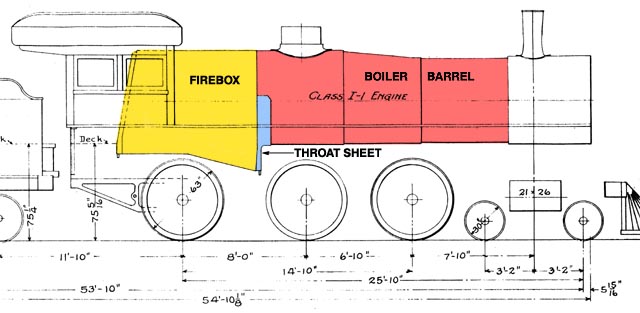

Looking at the other end of the firebox we can see where the rear tubesheet braces will be installed. Those are the wider-spaced holes below the field of closely spaced 2” tube holes. The braces are necessary because the holes in the tubesheet are above the top of the throat sheet so the braces are welded to the inside of the belly of the boiler. The braces are shaped like an elongated and squished “Z” so they can enter the hole in the tubesheet at a right angle and also lay flat on the boiler shell belly as they are welded in place.

The shot of the top of the boiler shows that just a ‘few’ stays need finish welding. You can also see that the steam dome base has been finished. The holes that do not have stays inserted are going to be some of the flexible stays and are awaiting the installation of the sleeves on the outside of the shell before the bolt itself can be applied and welded in place.

We do not have an anticipated return-to-service date for the 1385 but every weld is one step closer. Stay tuned to this webpage or our official Facebook and Instagram pages to keep up with most up-to-date information on 1385’s progress.

We appreciate the public’s enthusiasm to see the 1385’s progress first-hand; however, the contractor shops where the #1385 work is taking place are not open to the public. Anyone showing up at our contractor’s locations requesting to see the locomotive will be turned away. Please help #1385 return to operation as expeditiously as possible by respecting our contractors’ wishes.