The next item to be mounted to the backhead of the 1385 is the hydrostatic lubricator. That is merely a complicated name for the device that delivers steam cylinder oil to the valves and pistons as well as to the steam end of the engine’s air compressors. Steam cylinder oil is specially compounded to mix with and then be carried by the steam to all the internal moving parts.

The lubricator lives in the cab of the engine within reach of the engineer so he or she can keep a constant eye on this vital function. If the oiling stops the engine will begin to make some really ugly noises in a very short time and if not immediately corrected those noises become quite expensive.

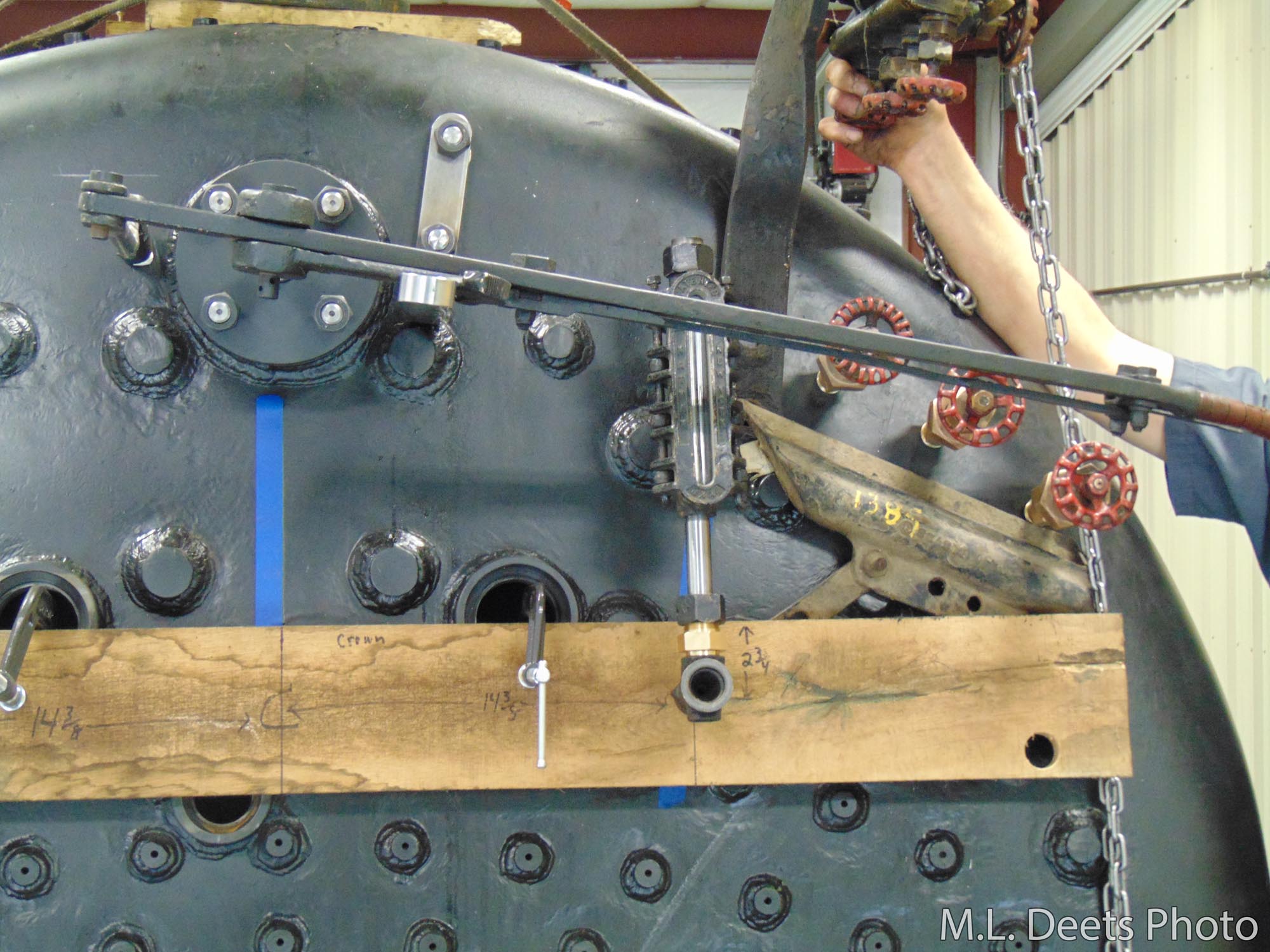

Once again the 3-D chessboard is set to mock up the placement of several pieces at once and the lubricator is hanging from the chain hoist. The bracket for the lubricator is mounted using 2 studs and its position is being verified between the try-cocks, throttle and one of the two required water gauge glasses.

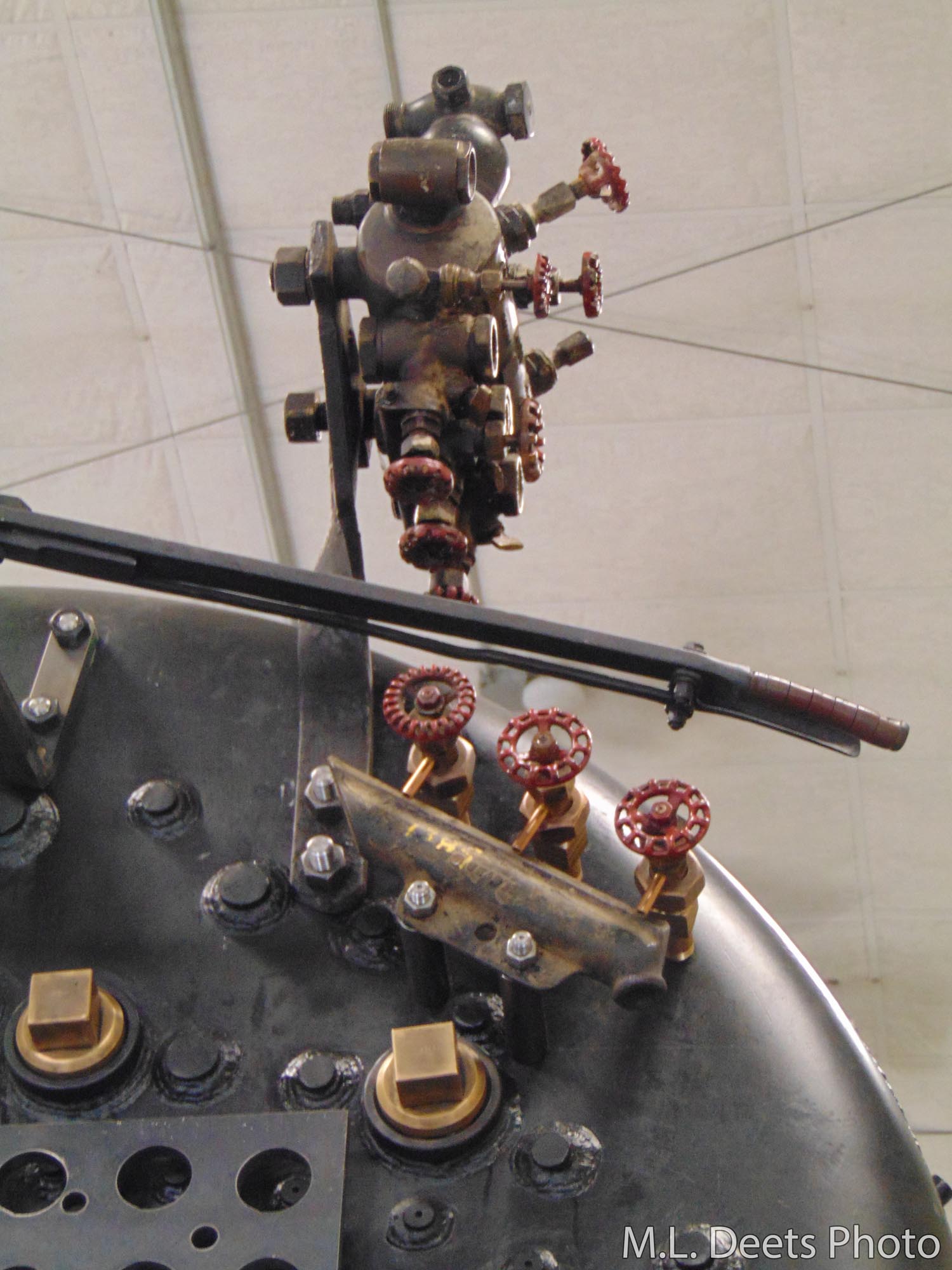

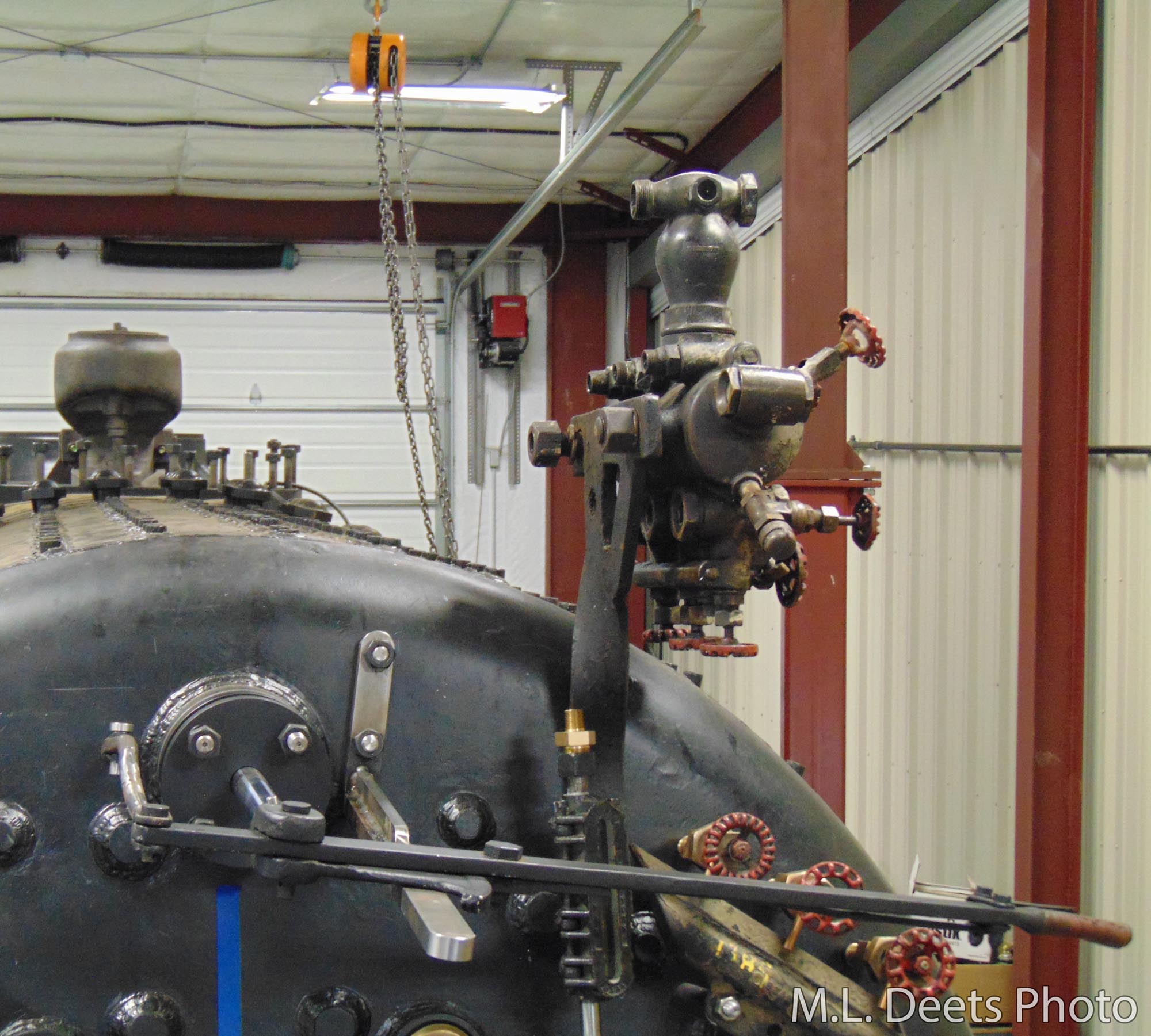

Here is the lubricator mounted in its final position showing how it is studded to the boiler. Our parting shot shows the upper right corner of the backhead and the top of the boiler with the body of the throttle peeking up out of the steam dome area. The dome was made to be removable to better facilitate maintenance work in the future.