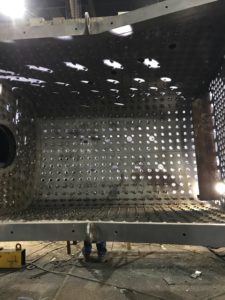

Progress continues with the welding of staybolts at Continental Fabricating. The boiler is now mounted to the positioner and like a huge rotisserie it can be rotated to allow the welders to work from the best possible position and comfortable welders make for better welds.

In these pictures, the boiler’s fireman (left) side is down to allow for work on the top of the wrapper sheet without having to set up scaffolding or work from a ladder. This minimizes or eliminates fall hazards. From the firebox side this will allow work to continue without welding overhead so the workers aren’t standing under a shower of sparks as they weld.

- C&NW #1385 boiler as of July 8, 2019. Photo courtesy Continental Fabricators.

- C&NW #1385 boiler as of July 8, 2019. Photo courtesy Continental Fabricators.

The below photo inside the boiler is a unique perspective that won’t be available much longer. The steam dome has not yet been welded in place so this allowed Continental Fabricator’s Tom G. to position the camera right in the top of the boiler shell where we can see the water side of the crownsheet and the rows of staybolts that tie the crownsheet and wrapper sheet together. We can also see the rows of staybolts yet to come, many of which will be flexible stays.