Patch Preparations and Driver Repairs

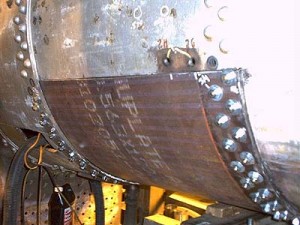

Indeed it was quite a successful weekend but it will be a day or two yet before I’ll get the pictures sent. The weekend actually started Friday, November 12th as Mike Wahl, Tye Hasheider, Don Engles and myself were able to come in and continue with the fitting process. The patch is nearly the right size so we are drilling the holes in the edges that will eventually become the rivet holes and bolting it in place as we go. We are working from the engineer’s side over to the fireman’s side to draw the steel into shape and determine how much more must be cut or ground off for the final fit. We’ve found that even with careful measurement and using the old piece as a pattern, the new patch still isn’t exactly the right shape. After all the bolts are in, some heat and persuasion will be applied to complete the job.

A magnetic base drill was rented to make the holes because this allows much more precise positioning and the magnet generally holds the drill quite still while punching through the steel. It was also used to drill out a broken bolt in the frame.

On Saturday, Mike, Tye, and Don returned and we were joined by Rick Peters, Kelly Bauman, Betsy Zonnerville, Jim Connor, Doug Klitzke, Al Joyce, Pat Weeden, and John Risley. Rick and John had earlier worked on repairing the cracks in the drivers and continued on with that task. The depth of the crack has to be defined by grinding away the old cast iron until the bottom is found. The area is then pre-heated and filled by welding. Many of the small cracks have been filled but there is still more work ahead.

Mike, Tye, and Don continued with the patch until Don had to leave, then Doug stepped in and gave a hand. Earlier Doug and Jim Connor unboxed a boiler tool that had been returned from loan to the Grand Canyon Railway. Shipping was not completely kind so they had to repair the box. Inspection showed no damage to the tool which is used for cutting a sealing seat in the steam dome of a boiler. It can also be adapted to the same work on a cylinder head.

Al Joyce continued turning out finished studs in the machine shop. Betsy and Kelly first performed some preventative maintenance on locomotive #4 and then inventoried and planned the use of a box of finished studs.

Jim Connor was even able to put a bit of time in on cleaning locomotive #7 to prep it for Santa Train. Our next organized work session is December 11 and 12 but we will also try to get some things done Santa weekend November 27 and 28. Bob Ristow is hoping to stay the week between Santa and Boyscouts to work on layout and fabrication of the new smokebox. He’s working to get a few people that may be able to help through that week. As it happens, my work schedule will have me off the 30th and Dec. 1st and I plan to be on the project.