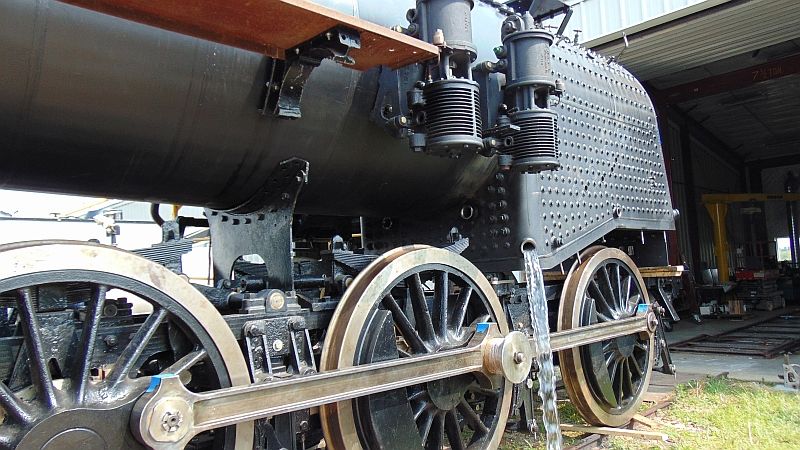

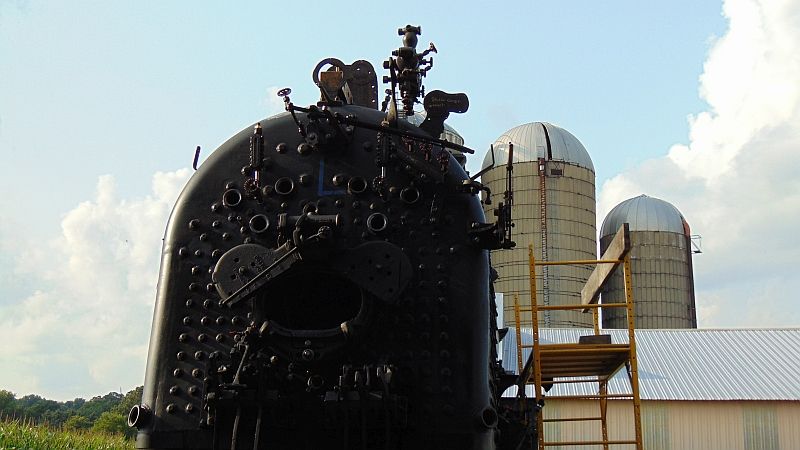

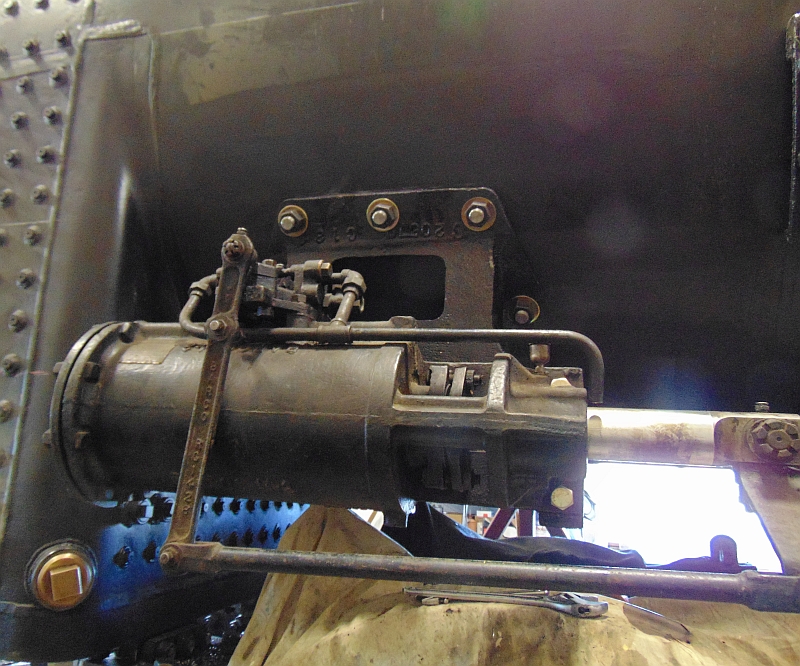

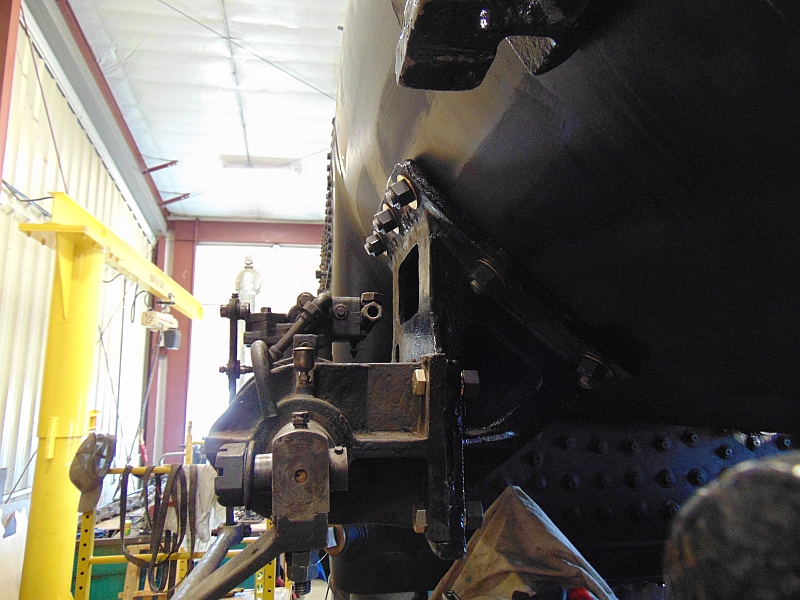

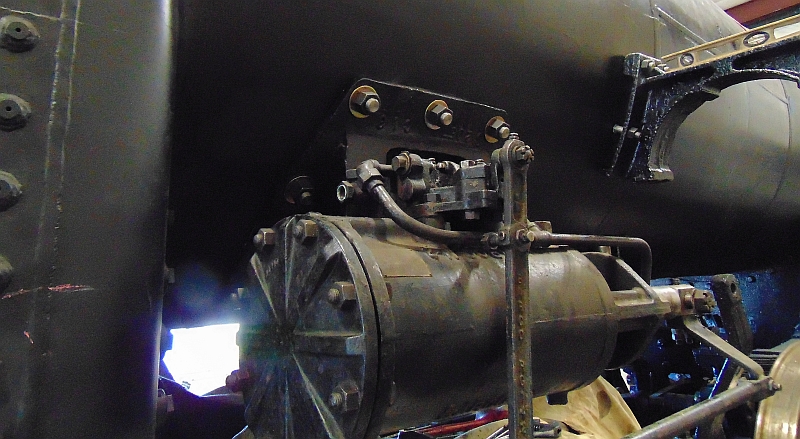

On July 20th Mike W., Pete D., Ed R., Mary S., Andy S. gathered at 8:00 AM to perform the first hydro test on the Chicago and North Western #1385 locomotive after all the studs and appliances have been added to the boiler. This is our own test to make sure that we have no leaks before the Federal Railroad Administration (FRA) witnessed test. We were able to get the boiler up to 90 degrees with a propane fired heater and a heated power washer. We slowly pressurized the boiler to around 125 PSI. The operating pressure of the boiler will be 200 PSI. This gave us a list of only a few items needing to be addressed before we perform our next test.

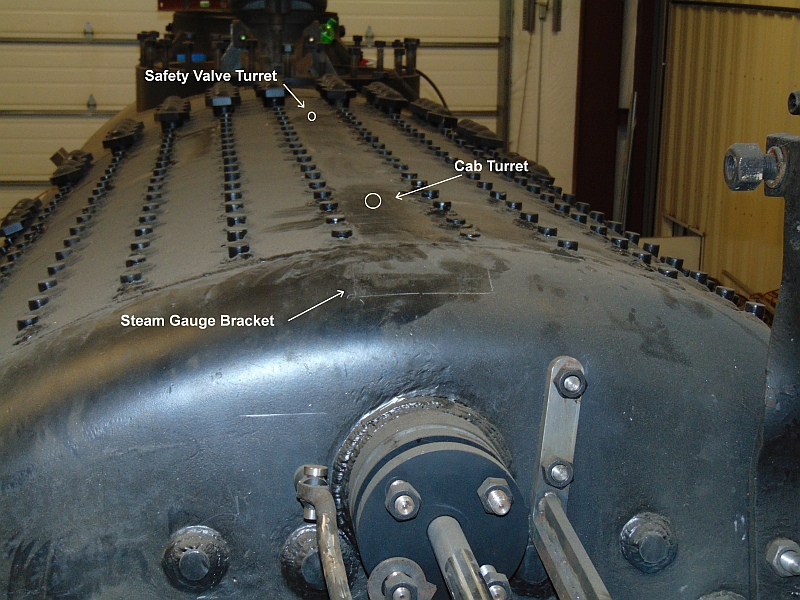

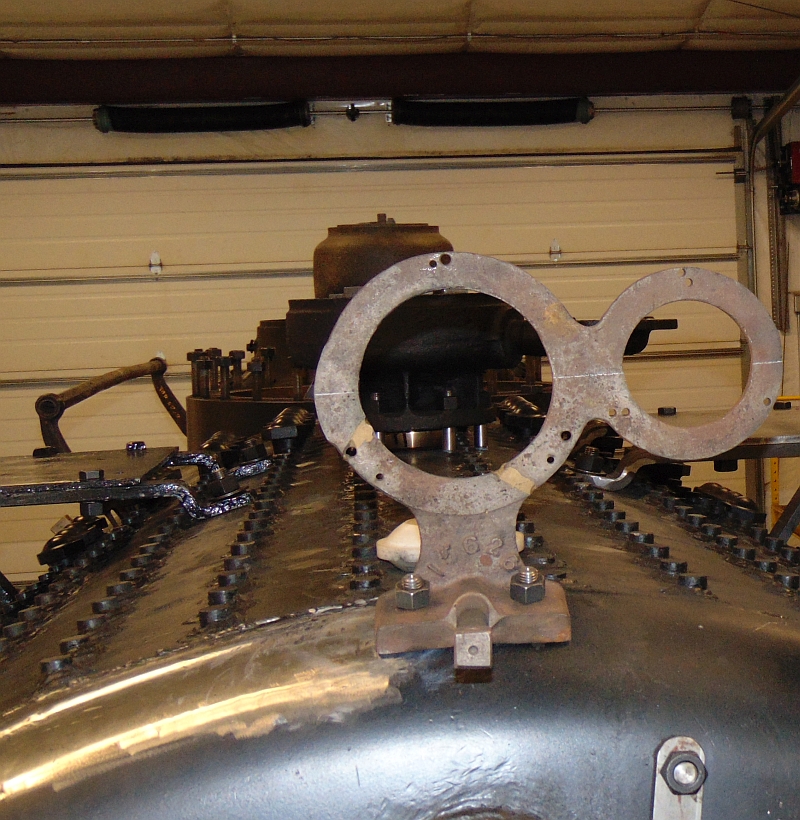

All washout plugs were found to be leaking as we found the sealing surfaces improperly seating. The sealing surface of the plugs are in the process of being trued up on the lathe now and the sealing surface of the sleeves will also be touched up. We have 2 staybolts that were found to be leaking and will be replaced very soon. We also had a small drip where the superheater header mounts to the front flue sheet, so the superheater units have been removed for access. We found about 5 studs altogether that were weeping and will be tightened.

Overall, this first test went very well, and we had no major issues. Plans are in motion to address the items we have and will be looking at doing our next hydro mid to end of September. Once we are confident we have all the items addressed, we will bring the boiler slowly up to 200 PSI and not over 120 degrees Fahrenheit. Then we will hold it and if no leaks occur then we will be ready to schedule our FRA witnessed hydro inspection.

This has taken a tremendous amount of capital and volunteer hours to get to this point. We have come very far and have done something at Mid-Continent we have never done before, a total rebuild of a steam locomotive to FRA standards. We have learned a lot in the process so far and still have a way to go. Please help support this project with funding and general support of our steam team. Without everyone pulling together we would not be as close as we are. A big thank you to our team and all our members and railfans that have supported us! We will not let you down.

Thank you for your help and support.

Andy S.

President

Mid-Continent Railroad Museum

Please visit the Donations Page to make a contribution toward the 1385 or other museum projects.