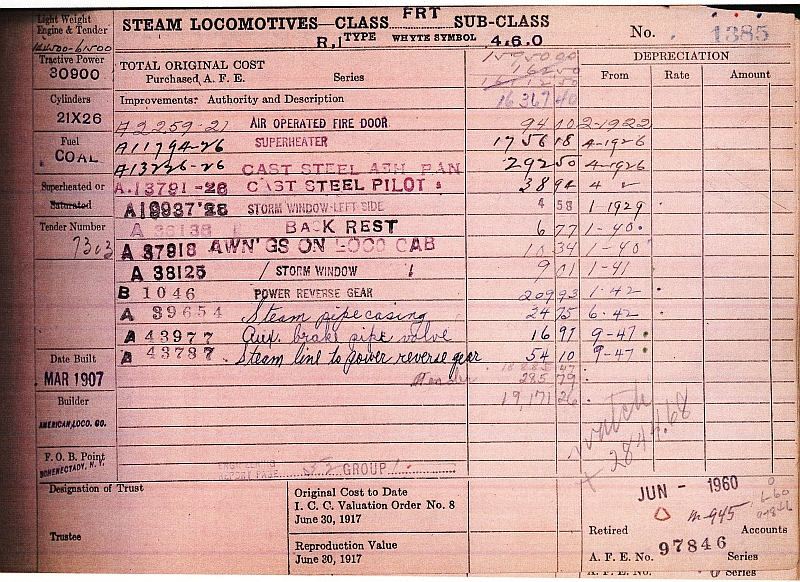

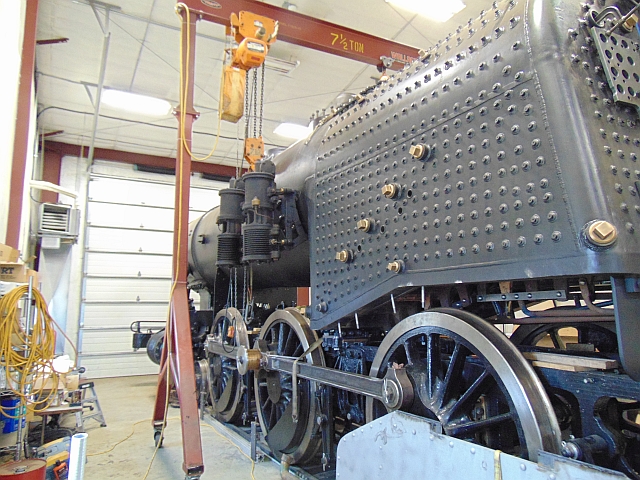

Sometime after the first part of 1942, the C&NW changed the “face” of 1385. They were required to. The steps from the front bumper beam to the smokebox of the engine were changed to conform with a mandate from the Interstate Commerce Commission. The ICC was the federal board governing, amongst other things, the interstate dealings of the railroads from 1887 to 1996 and what was left of the ICC became the Surface Transportation Board thereafter. The range of the many things under their purview included safety appliances and devices on rail equipment and one of those things was the runboard steps on the front end of locomotives.

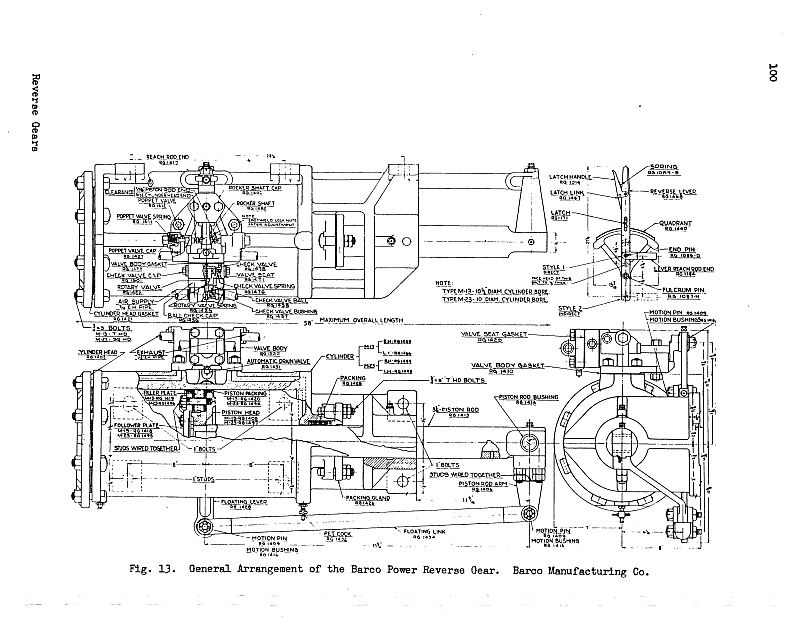

This update will be using “runboard” as that is the terminology the C&NW uses throughout their drawings for 1385, although the components are known by numerous other names, including running boards, foot boards, and tread plates. You will note the portion of the drawing below was issued January 12th, 1942, and elsewhere on a portion of the drawing not shown states “For all R-1 class engines with old boilers.” The 1385 is indeed an R-1 class and has what the C&NW called the old boiler.

A best guess of the reasoning behind this requirement is that it made it so all vertical spaces between steps on the runboard would have a solid plate so a person’s foot could not slip between steps.

Here is a photo of sister engine C&NW #1402 showing one of the R-1 class step designs before the ICC required modifications.

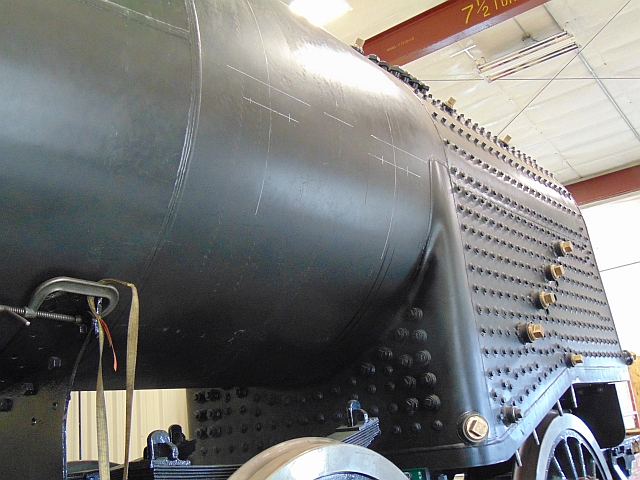

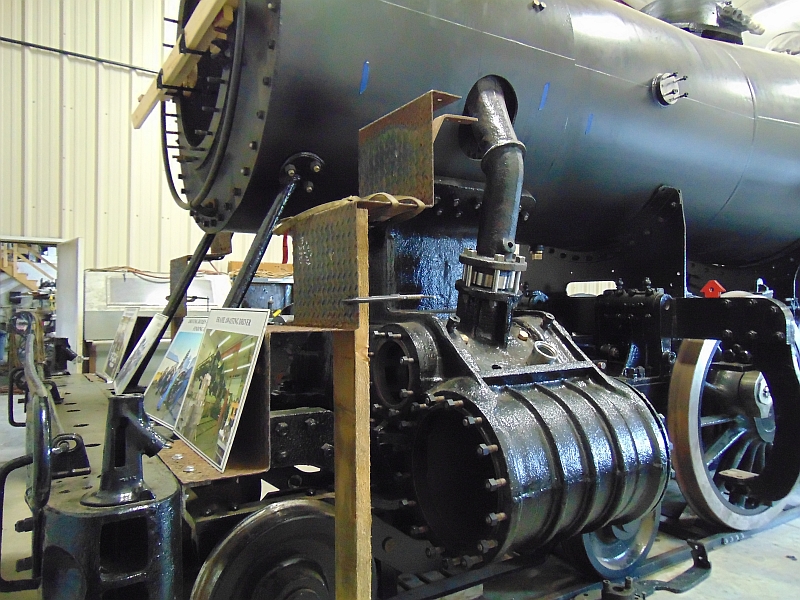

Below, we see the old steps propped up into place to be able to check alignment and attachment.

On the engineer’s side you can see how warped and cracked the attachment edge of the original step has become.

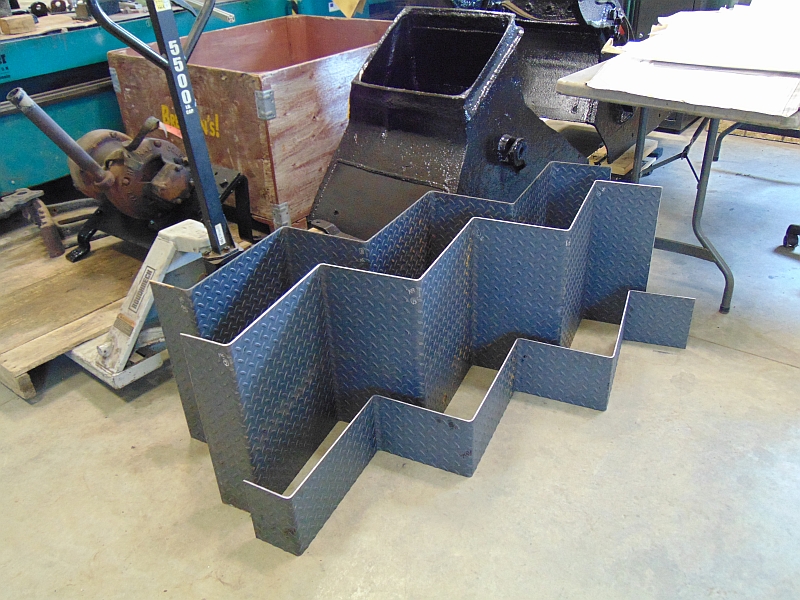

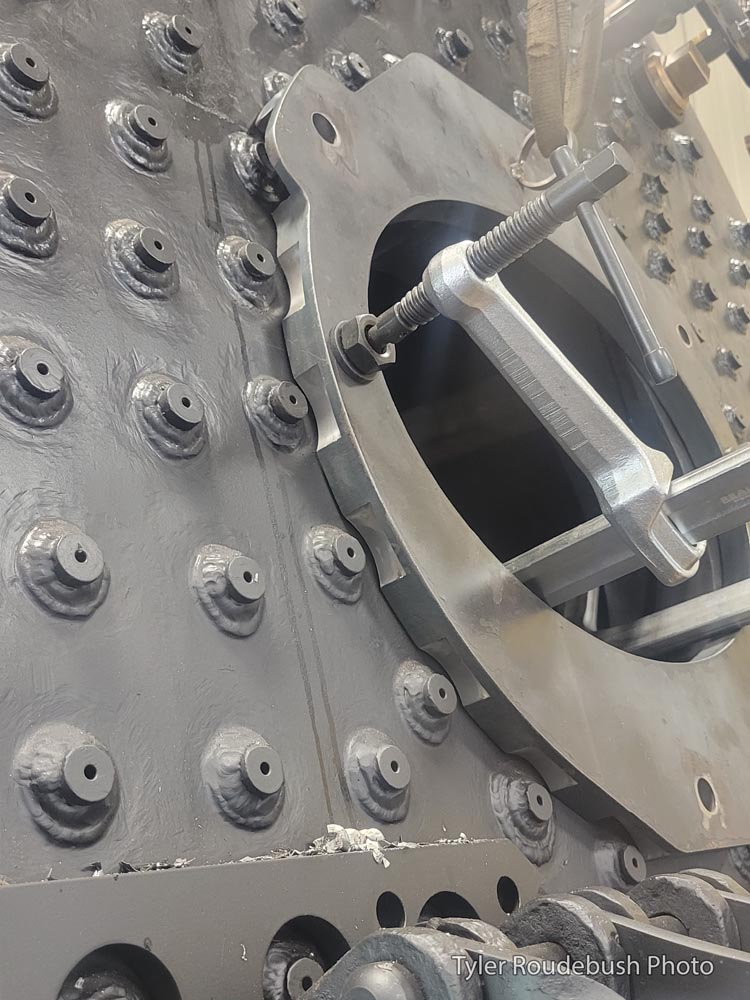

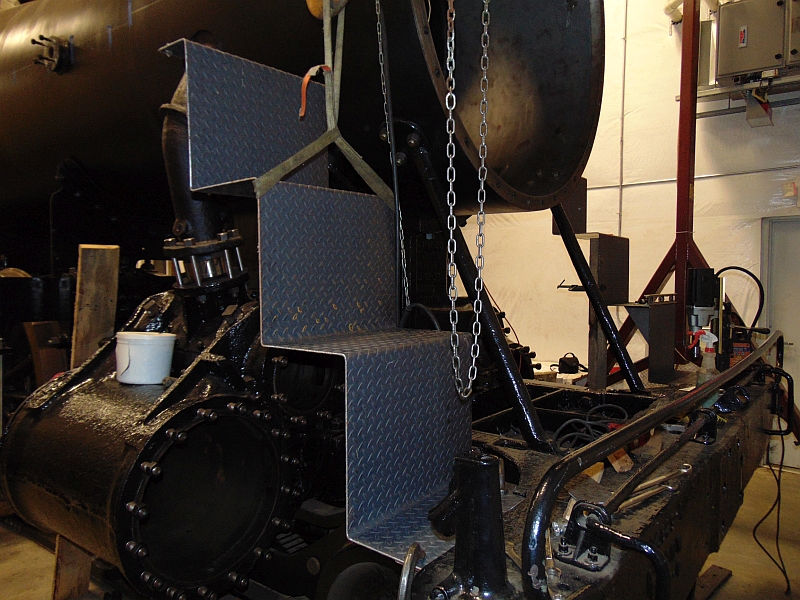

A new plate of steel was purchased, sheared, and bent to form the replacement steps.

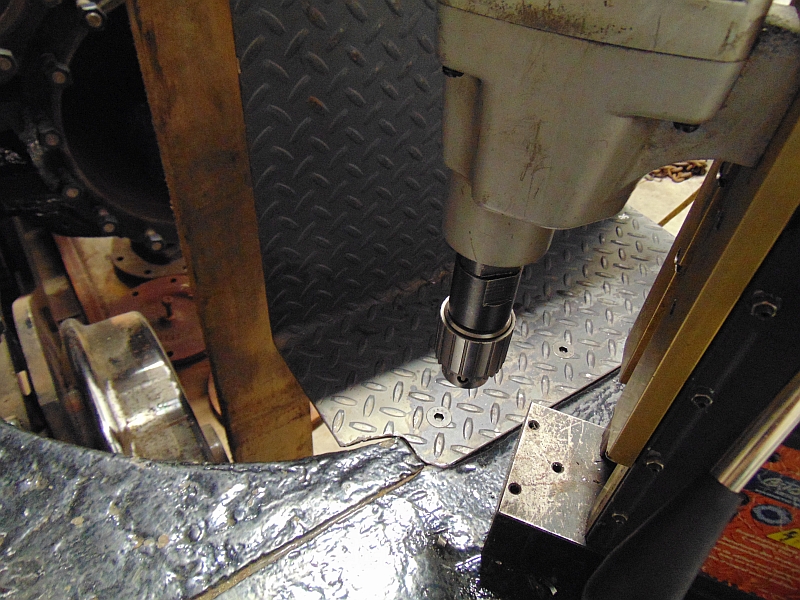

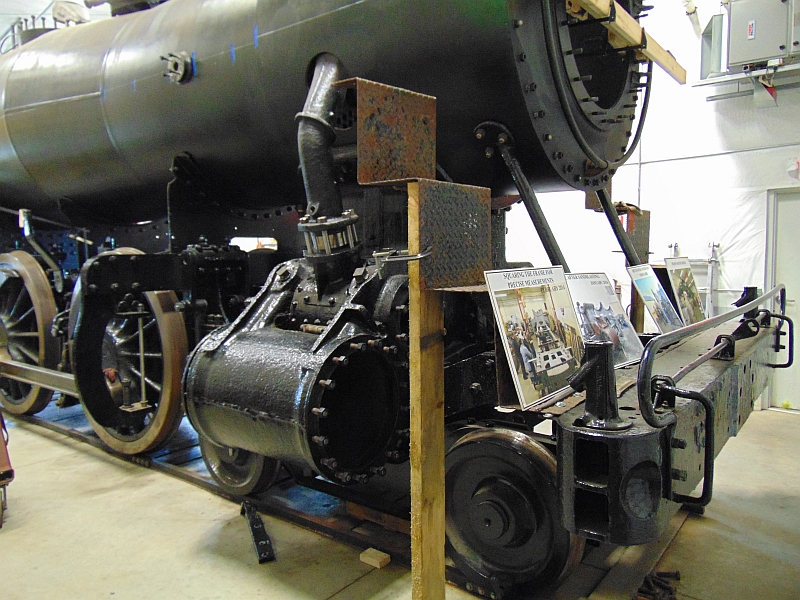

Here, we see the new engineer’s side step has been trimmed to fit the bumper beam and is clamped in place, ready to be drilled for the mounting bolts.

On the fireman’s side the magnetic base drill has already made the holes and the bottom mounting bolts are in place.

The runboards that get attached to the smokebox and connect to the steps discussed in this update will be the next pieces of the puzzle to receive attention.

Donate to the 1385 Restoration Fund

The Chicago & North Western #1385’s restoration relies heavily on donations. We’d love to bring this piece of history back home to Mid-Continent and have it running again. If you like seeing these updates and would like to help bring this project to fruition, please consider donating!

To donate by mail or by phone, visit our Donate Page.