The next C&NW no. 1385 steam locomotive restoration workday has been announced for Friday, April 6th beginning at 9 a.m in Mid-Continent’s engine house. Tasks are to include finishing removal of the running boards and exhaust stand. Work on removing the cylinder saddles may also begin if time allows. No prior volunteer experience or sign-up is necessary. All that is needed is a bit of muscle and willingness to get a bit dirty.

Category Archives: C&NW #1385 Status Updates

Preparations to Remove the Boiler

A work session was arranged for Saturday, January 7, 2012 to continue work started before the holidays on the Chicago & North Western no. 1385. The primary goal in these recent work sessions has been to remove exterior appliances from the locomotive boiler and frame. This work is being done in preparation for boiler removal from the frame and the shipment of the running gear to a shop for rebuild. Having sat idle and exposed to the elements for much of the time since it last operated in June of 1998, removal of many of the pieces have proven to be no easy undertaking and to make matters even more difficult, items like the running board brackets have not been removed from the boiler in many decades.

The crew for the day was led by Ed Ripp and Pete Deets. Assisting were Kelly Bauman, Richard Colby, and engine house first-timers Adam Stutz and Jeffrey Lentz. Jim Busse was also on hand and performed some much-needed cleaning and organization of the engine house and surrounding area.

With the 1385 parked in the engine house and the large south door open to let in the sun and unseasonably mild temperatures, work began. Pete, Ed and Richard all took turns climbing into the smokebox to clean rust from the blast pipe and smokestack mountings. Removal of the engineer side air reservoir brackets also took place. Work proceeded slowly as the rust necessitated most bolts be cut with a torch.

Close quarters between the 1385 and the engine house wall on the fireman side of the locomotive required that the R-1 be towed by MCRY no. 4 to a location just outside of the engine house to reduce fire risk from the shower of sparks. Once outside, work was able to proceed on removal of the air reservoir tank brackets and running boards. Work also began on the removal of the smokestack. With the more advanced work left largely to Pete and Ed, restoration newcomers Richard, Adam and Jeffrey took on the removal of the pilot support brackets at the front of the locomotive, a job suited to their flexibility.

Work continued as darkness descended. Finally, with too little light to safely continue, work was halted at about 6 pm and the 1385 was rolled safely back into the engine house to await the next work weekend.

- The 1385 work crew for January 7, 2012. From left to right, Jeffrey Lentz, Adam Stutz, Richard Colby, Kelly Bauman, Pete Deets, and Ed Ripp.

- C&NW 1385 in the engine house. Jeffrey Lentz photo.

- C&NW 1385 in the engine house. Jeffrey Lentz photo.

- C&NW No. 1385 (left) and Western Coal & Coke No. 1 (right). Jeffrey Lentz photo.

- Ed Ripp inside the firebox as he clears rust and debris from the blast pipe mounting. Jeffrey Lentz photo.

- Adam Stutz contorts his body to try to better reach the pilot mounting bracket bolts. Jeffrey Lentz photo.

- Pete Deets uses a torch cutter to loosen the air reservoir mounting brackets and running boards. Jeffrey Lentz photo.

- Pete Deets uses a torch cutter to loosen the air reservoir mounting brackets and running boards. Jeffrey Lentz photo.

- The 1385 is towed from the engine house to minimize fire risk. Jeffrey Lentz photo.

- Ed is in good spirits despite the rust’s best attempts to thwart plans for removing the smokestack. Jeffrey Lentz photo.

- View from the 1385 running boards looking toward the absent cab. Jeffrey Lentz photo.

- Ed navigates the Lull (forklift) into position to remove the smokestack as Pete observes. Jeffrey Lentz photo.

- By late afternoon, the smokestack finally is freed from the smokebox. Jeffrey Lentz photo.

- The smokestack has seen its better days. It has had several repairs made over the years to keep it going. When the smokestack was being preped for removeal, it was found that several of the old welds had broken. At some point, a few pieces were even welded to the smokebox to keep them in place. Jeffrey Lentz photo.

- Daylight made an existing crack to the front of the smokestack readily visible. Jeffrey Lentz photo.

- Pete creates a shower of sparks in the process of beginning the removal of the fireman side running board. Jeffrey Lentz photo.

- Richard Colby takes on the removal of the last pilot mounting bracket. Jeffrey Lentz photo.

- All the while, Jim Busse continues to tidy up the engine house. Jeffrey Lentz photo.

- Kelly Bauman as seen as through the hole where the smokestack previously stood. The welded-on piece from the smokestack is seen remaining to the left. Jeffrey Lentz photo.

- Removal of the fireman side running board continues as darkness descends but it proved to be too stubbornly set in its place to remove before it became too dark to continue. Jeffrey Lentz photo.

- With work done for the day, the 1385 (right) was brought back into the engine house next to the Western Coal & Coke No. 1. Jeffrey Lentz photo.

Cab on the Move

Departing from the last several updates which focused on the restoration of C&NW #1385’s tender, this update features news on the locomotive itself. In the inspection of the locomotive during the fall of 2011, there was found to be a great deal of deterioration on the locomotive cab. The 1385 Task Force charged with leading the restoration effort reviewed the options for rebuilding the cab and decided to use CJ Woodworking out of Fond du Lac, Wisconsin. Details of the rebuild were finalized with the contractor and plans put into place for moving the cab to ready it for transport. The cab had been stored on a flat car at Mid-Continent while the locomotive awaited restoration. This happened Friday, December 23, 2011 during a restoration workday. Museum President Jeff Bloohm and Superintendent of Operations Kelly Bauman took care of the move so the cab was accessible for lifting by our Lull operator Ed Ripp. CJ Woodworking arrived around 10:00 am and before lunch they were on their way back to Fond du Lac with the 1385 cab.

CJ Woodworking will be building a new cab to the original Chicago & North Western drawings we have obtained from Lake States Railway Historical Association of Baraboo. The cab will be made from white oak as originally specified by the C&NW.

Also shown are some photos taken by Mike Wahl, Project Engineer during an inspection in July that shows some of the deterioration of the cab.

- 1385 cab being removed from storage on an MCRM flat car in preparation of being rebuilt. Chuck Ham photo.

- 1385 cab being loaded onto trailer for shipment to rebuild shop. Chuck Ham photo.

- 1385 cab leaving to be rebuild at a shop just outside of Fond du Lac, Wisconsin. Chuck Ham photo.

- 1385 cab interior before rebuild showing deterioration to side sill. July 2011. Mike Wahl photo.

- 1385 cab before rebuild showing deterioration to front cab post and window frame. July 2011. Mike Wahl photo.

Tender History and Plan

Written by Mike Wahl

For this installment I will start with the history we have gathered about the original 1385 tender.

The original Chicago & North Western builder’s specifications from March of 1907 call out the following specs for the tender. I have summarized part of the information below.

Frame: The frame is to be substantially built of 13 inch steel channels and thoroughly braced.

Truck, Wheels, and Axles: The tender will carry two 4 wheel trucks. It was to have 5 1/2 x 10 inch journals with 33 inch wheels.

Tank: The tank is to have a capacity of 7500 gallons of water and 10 tons of coal. It is to be made of steel ¼ inch in thickness.

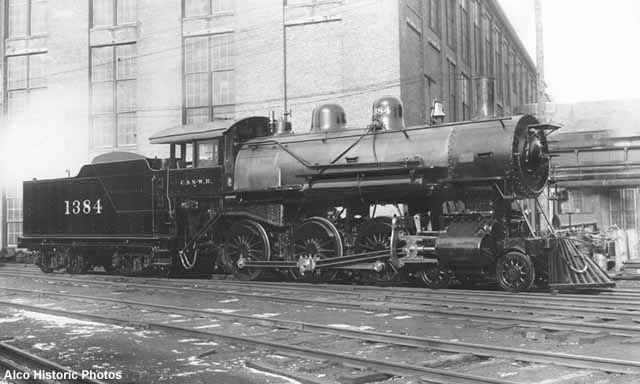

Included below is a picture of the 1384 which shows what the tender of the 1385 looked like in March 1907 when completed by the American Locomotive Company’s Schenectady Works.

The Chicago & North Western kept valuation records on all of their equipment. Each locomotive and tender was assigned a number to keep track of the cost spent on the equipment. The valuation record number for the locomotive was the locomotive number, the 1385 was 1385. The tenders were given a unique number. In the case of the 1385, tender number 7303 was with the locomotive when purchased by MCRM.

Using this record we can tell a few things about tender. On 10-19-1926 the tender received a cast steal frame, replacing the original steel channel frame, for a cost of $235.73. This is the first entry on the valuation record. It also states that the only engine it was in operation with was the 1385. So we do know that from 10-19-1926 until it retirement this was the tender the 1385 used. At this point we can only speculate that this was the tender it used from 1907 until 1926.

If you examine the photo of the 1384’s tender verses the tender photo’s of the 1385 I have included you can see some differences in the coal pocket area. The R-1 class locomotives with 7500 gallon tanks had a tender modification done, to add more coal capacity. They added radius wings to the edges and height to the front board to increase the tender’s capacity. There is a drawing called Tender Tank – Alteration for increased coal capacity date March 7th, 1944 that shows this change.

The Tender Plan

As I stated previously, the tender will be broken down into smaller tasks. They are the tank, tender frame and tender trucks.

Tank: The plan for the tender tank is to engineer and design a new welded tender tank to replace the original. The current tank will be used for reference along with the original drawing in the design of the new tank. The design goal of the new tank is to preserve a look as historically accurate as possible with the utilization of modern materials and manufacturing processes. To make this a restoration, not a completely new tank, we plan to use as much of the original hardware as possible like the coal board brackets, hatch parts and any other components that are salvageable.

Tender Frame: The tender tank was removed from the frame a few weeks back which allowed for us to perform an inspection. The overall condition of the frame was good. The contractor has removed the components from the frame, sandblasted it and it is in red oxide primer. The next step on the frame will be to examine it after cleaning and priming to determine what repairs are needed. I have included a picture of the frame taken by our contractor.

Tender Trucks: The tender trucks are in very bad condition. When the tender was parked at the end if the line at Quartzite Lake the trucks were buried in dirt and gravel. The team is currently evaluating rebuilding using roller bearing replacements as an option for the trucks. This decision will be made down the road once all of the options are evaluated.

Developing a Plan

Written by Mike Wahl

During my visits to North Freedom the last couple weekends I have been asked, what’s going on with the 1385, what’s the plan? My response has been we are doing just that, making a plan.

To make any project successful a good plan, strategy and expected final outcome is needed. To make a good project plan the project must be broken down into smaller parts. There’s an old joke that goes: How do you eat an elephant? Well, one bite at a time of course! The next question then is what bite do we need to take first? To determine this we needed a strategy and scope of work. With a defined strategy, we can choose where to start and set our priorities. With a defined scope we have a formal document that captures and defines the work activities, deliverables and timeline for our contractors and vendors.

So enough with the philosophy and more on to the plan and strategy.

We have broken the 1385 project down into parts of the locomotive. They include major components of the locomotive like the running gear, boiler, tender, appliances, and cab. These components will then be broken down further to better define the scope, priority and timeline. We have begun this process on the locomotive. Our first focus has been the tender.

Just for some foresight on my next post, we have broken the tender down into 3 sub-components or tasks. They include the tender tank, tender frame and tender trucks. Each one has been evaluated and a plan and strategy has been developed. I will start a new post soon on the tender with more details. I have included a few pictures as a sneak peek of what the tender looks like today.

In closing, during my studies, I had a project management professor at UW-Stout sum up “How to eat an elephant” in the following manner. I think this sums up our project goals well.

“Take small bites out of your elephant. Take the right bites. But most importantly, determine what your elephant will look like when you’ve eaten the whole thing this will help keep you focused on the results, not the work.”

- C&NW 1385’s original tender as of June 25, 2011.

- C&NW 1385’s original tender as of June 25, 2011.

- C&NW 1385’s original tender as of June 25, 2011.

- Coal pocket detail of C&NW 1385’s original tender as of June 25, 2011.

- One of C&NW 1385’s tender trucks as of June 25, 2011.