The Flannery Bolt Company is long gone but their products live on as their staybolt and staybolt accessories are reproduced today for projects like the Mid-Continent’s Chicago & North Western No. 1385. In the steam era staybolt production and replacement were a regular occurrence and such parts were readily available in large quantities. Even in 2018 there are at least two shops readily producing them as a specialty item, but for the 1385 project Mid-Continent has opted to keep it local, producing them in-house at SPEC Machine where the bulk of the locomotive’s overhaul and assembly is taking place.

1385 project volunteer Pete Deets explains, “We decided to have Steve Roudebush [owner of SPEC Machine] make them as the best way to control the cost and delivery schedule.” He adds, “The bolts to go with the sleeves and caps are on the way… there are 72 flexible staybolts on the 1385 but there are also a few hundred rigid stays that will go into the boiler.”

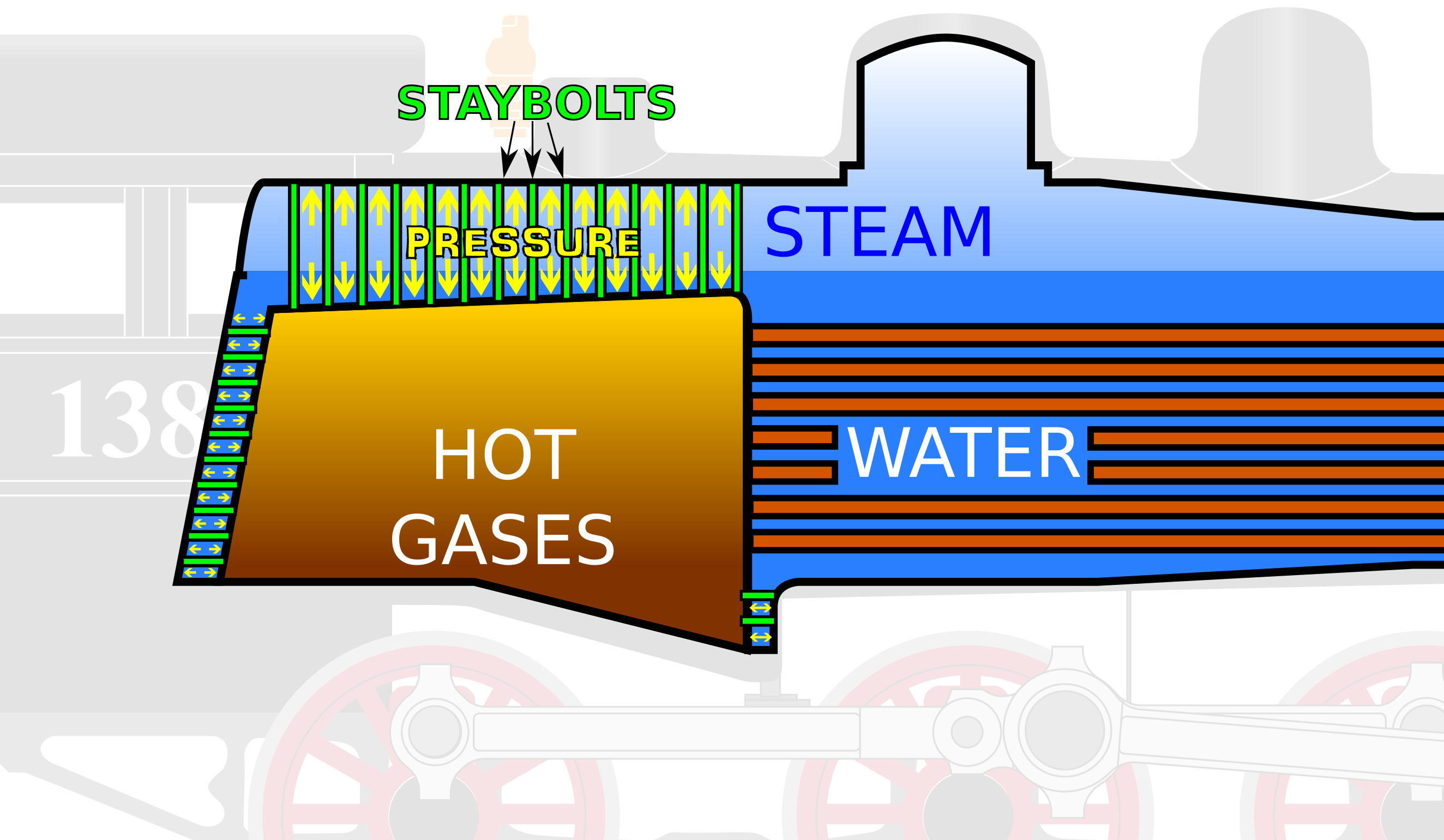

The majority of the boiler is cylindrical, a naturally strong shape, but there are also some flat and irregular surfaces within the boiler too, especially around the firebox. With the intense pressures up to 250 psi inside 1385’s boiler, these surfaces would weaken, bow, and eventually fail without staybolts to support them.

The flexability afforded by a flexible staybolt is critical to maintaining the boiler’s strength while still allowing for the expansion and contraction that occurs as temperatures change from one extreme to another within the boiler. Deets explains:

A flexible staybolt has a ball shape on one end and is threaded on the other. The ball end fits into and will be held by the cup shape of the inside of the sleeve. The sleeve will be welded on the outside or wrapper sheet of the boiler above the firebox. The bolt is then dropped into the sleeve and the threaded end is screwed into a threaded hole in the firebox. The bolt is hammered or “upset” to cause it to swell into the threads and form a steam tight seal and a copper gasket is applied with the cap to seal the sleeve end. The ball end of the bolt can actually swivel in the cup shape of the cap and it allows the firebox to move in relation to the wrapper sheet of the boiler as the engine goes down the road. [Locomotive designers] found that allowing that slight bit of movement was better overall for the boiler than trying to hold every bit very stiff and rigid. If things were too rigid the boiler would break the staybolts anyway. It was also noted there were fairly specific areas of a boiler that were prone to breaking stays so the Railroad Master Mechanics Committee came out with recommended patterns of placement for the flexi’s to alleviate or at least minimize the breakage.

- New flexible stay caps and sleeves were fabricated in January 2018 by SPEC Machine for C&NW 1385. The accompanying bolts are currently in production. Photo courtesy SPEC Machine.

- Heat numbers are stamped onto C&NW 1385’s flexible staybolt caps. Photo courtesy SPEC Machine.

- Flexible staybolt cap and sleeve detail. Photo courtesy SPEC Machine.

The photos of the staybolt caps reveal a series of numbers stamped on each one. The number represents the part’s “heat number.” That is a jargon from the steel industry as they refer to every batch of iron or steel (or any metal) that comes out of a furnace as a “heat.”

Deets elaborates on the importance of heat numbers:

That number is vital because every piece of metal that goes into the pressure retaining portion of the boiler must meet very specific requirements of physical strength, mechanical properties and chemical properties and we have to be able to prove the materials we use meet those specs. Every batch of steel made is tested for chemistry and physical properties and is assigned a unique number. The records of those batches made for specific applications such as boiler plate follow the steel through the finishing process of the mill and each piece is marked with the heat number and other information. Those records are the certification that this particular batch or heat number meets this specific set of requirements and we must get a copy of and keep on file the material certifications or “certs” for short. That heat number represents the “pedigree” of each of those parts.

The below YouTube video produced by Wasatch Railroad Contractors while working on a different locomotive restoration provides a good illustration and explanation of how flexible staybolts work.

Last but not least, SPEC Machine has also been busy finishing up more work on 1385’s brake equipment. Brand new brake heads were cast last summer (see post from Sept. 1, 2017) and are now being machined in preparation for installation.