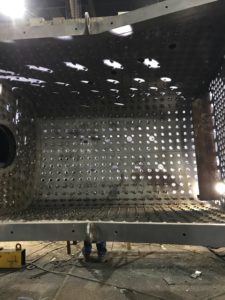

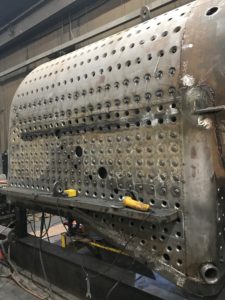

Welding and patience continues at Continental Fabricating as more stays are completed on the R-1 boiler. No, the pictures are not upside down, that is merely the positioner at work to allow the greatest productivity and weld quality possible. The steel forging which makes the base of the steam dome has been tack welded in place and you can see the welder’s feet as he makes the root and fill-in welding passes while he’s standing on the floor.

The other parts of the steam dome are being fitted together and the welding has been partially completed and soon will be done. For the new boiler we have adopted a more European approach by having a removable steam dome. This will make maintenance and inspection tasks much easier in the years to come.

Photos are courtesy of Continental Fabricators.

- 1385’s firebox is upside-down to facilitate easier working conditions. Photo courtesy Continental Fabricators.

- Staybolt installation is nearing completion. Photo courtesy Continental Fabricators.

- A worker stands partially inside the boiler as he welds the base of the steam dome in place. Photo courtesy Continental Fabricators.

- Steam dome components. Photo courtesy Continental Fabricators.