NORTH FREEDOM, WI – Mid-Continent Railway Museum is excited to announce it has received a $10,000 grant from the John H. Emery Rail Heritage Trust (ERHT) for use on the next phase of restoration on Mid-Continent’s Duluth South Shore & Atlantic Railway (DSS&A) sleeping car “DULUTH”.

Sleeping cars were an integral part of passenger rail travel during the “Golden Age” of railroads. Extensive research has revealed that the DULUTH sleeping car is historically significant as it is the oldest and most complete standard gauge wooden sleeper car known to survive in the United States.

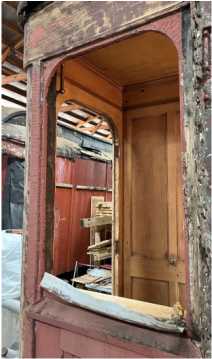

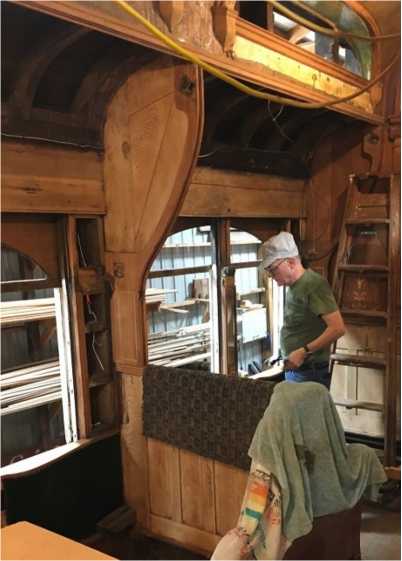

The DULUTH was built in 1902 by the Barney & Smith Car Company and operated as a 10-section sleeping car on the DSS&A’s passenger train between Sault Ste. Marie, MI and Duluth, MN until 1934. After being taken out of service, it was sold to a private resident of Laurium, MI. and it spent the next 81 years as a summer cabin on the shore of Lake Superior. In 2015, the car was graciously donated to Mid-Continent Railway Museum (MCRM) by Lt. Col. Robert and Elizabeth Krasche to assure the long-term preservation of the railcar.

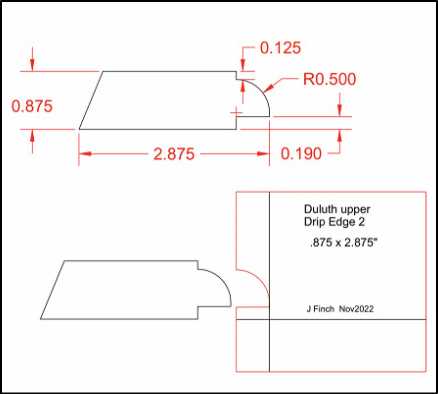

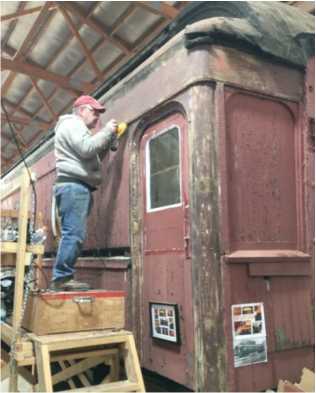

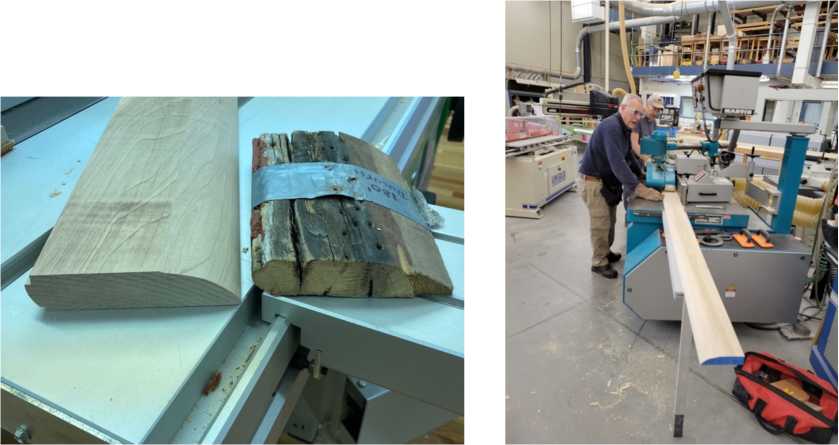

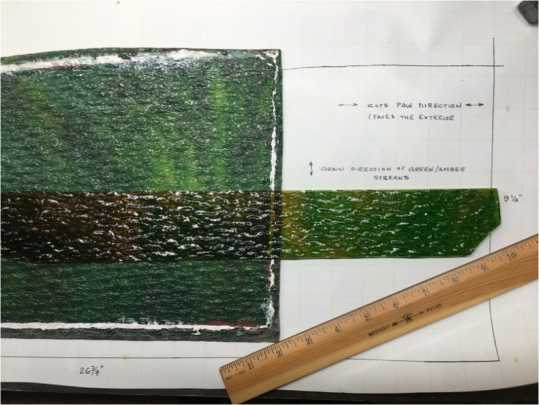

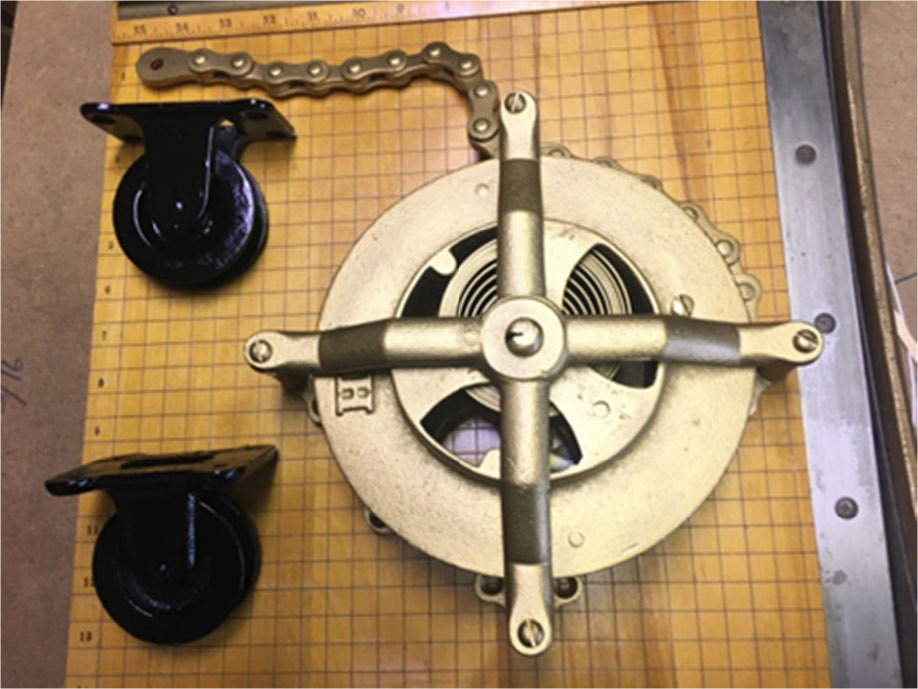

Since its arrival at MCRM restoration crews have taken significant steps to return the DULUTH to operating condition, with volunteers putting over 2,800 hours of work into the car’s restoration so far. The funds from this grant will further the next phase of the DULUTH’s restoration which will feature work on the sleeping compartment, upholstery work, replicating stained glass windows, and installing new wood siding on the exterior of the car.

This next phase of work is projected to require approximately $125,000 and 3,000 additional hours of volunteer labor. Additional grants and donations are being sought to raise the funds needed to complete this work. Any Individuals or organizations interested in donating funds, professional services, or volunteer labor to help with the DULUTH project are encouraged to contact the museum at 608-522-4261 or email inquiries@midcontinent.org.

Once restored, the DULUTH will be placed indoors on public display. Mid-Continent will also operate the DULUTH on the museum’s rail line several times a year, re-creating and preserving the rail passenger travel experience.

This is the third grant the John H. Emery Rail Heritage Trust has awarded to the DULUTH project. The Trust previously awarded $9,000 in 2018 and $15,000 in 2022 and has supported other museum projects as well, including the C&NW #1385 steam locomotive and the museum’s coach car #595. Mid-Continent Railway Museum is genuinely appreciative of John H. Emery Rail Heritage Trust for its repeated and generous support of the museum’s mission.

About the John H. Emery Rail Heritage Trust

The John H. Emery Rail Heritage Trust was created by John Emery, a native of Chicago, and a lover of the classic passenger trains of America. The Trust was founded as a way to support Mr. Emery’s interests in the passenger trains of the 1920s through the 1950s. The Trust operates as a tax-exempt 501(c)(3) foundation.

About Mid-Continent Railway Museum

Mid-Continent Railway Historical Society–also known as Mid-Continent Railway Museum–is an outdoor, living museum and operating railroad recreating the small town/short line way of life during the “Golden Age of Railroading,” with operating trains, educational exhibits, and displays of restored rolling stock. In 2023 Mid-Continent will be celebrating its 60th anniversary of sharing railroad history with museum visitors.