Brake-ing News

The braking system for Chicago & North Western #1385 consists of an iron shoe pressed against the steel wheel. The shoes are held by the brake head and held on the brake head by a key. The brake head is attached to the brake beams and through a system of levers and hangers the brake beams get their motion and power from compressed air applied to the brake cylinders.

The brake heads on the 1385 were worn out so we ended up having a pattern made and getting new brake heads cast from steel. Project volunteer Pete Deets got a couple photos of Steve machining the last head to fit the curvature of the brake shoe. There are also a couple of shots of the key, head & shoe on the bench.

- Steve R. of SPEC Machine machines a new brakehead to proper dimensions. Pete Deets photo.

- Machining one of 1385’s brakeheads. Pete Deets photo.

- Cutting fluid is sprayed onto the work area to assist with the process. Pete Deets photo.

- The newly machined brake head next to one of 1385’s brake shoes. Pete Deets photo.

- The brake head gets secured to the brake beam (not shown). Pete Deets photo.

- The curved brake shoe fits the curvature of the wheel and applies force against the wheel during braking. Pete Deets photo.

- The brake shoe is held in place in the brake head with a key, seen here. Pete Deets photo.

Since these photos were taken the brakes have already been installed onto the 1385’s running gear. SPEC Machine is now turning its attention back to the cab. Upcoming tasks include installing the cab roof’s protective rubber roof installed to keep the weather out and installing the cab electrical system.

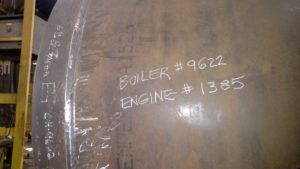

On the southern front, progress has continued to at the Continental Fabricators shop in St. Louis, Missouri where the 1385’s new boiler is taking shape. In mid-July 2018, the boiler underwent the first of what will be numerous inspections from the Federal Railroad Administration as the locomotive comes together. In the process of going through its first inspection it earned a boiler number, 9622, for FRA tracking purposes. This means for the first time the new boiler is officially recognized as part of the locomotive. The inspector spent a couple of hours reviewing the parts and pieces and was satisfied with the work to date.

- C&NW 1385’s new smokebox on the factory floor in early June 2018. Photo courtesy Continental Fabricators.

- C&NW 1385’s 1st, 2nd and 3rd course shell with front flue sheet welded in. Photo taken early June 2018. Photo courtesy Continental Fabricators.

- 1385’s firebox partially fit to mud ring. Early June 2018. Photo courtesy Continental Fabricators.

- A 1385 wrapper side sheet under production. Photo courtesy Continental Fabricators.

- C&NW 1385’s new backhead. Photo courtesy Continental Fabricators.

- Outer throat sheet. Gary Bensman photo.

- Right side wrapper sheet. Gary Bensman photo.

- Detail photo of the right front corner of the firebox at the mudring. Gary Bensman photo.

- Door hole in door sheet. This is where the fireman will shovel coal into the boiler. Gary Bensman photo.

- C&NW 1385’s new backhead. Gary Bensman photo.

- The new boiler has been assigned an official boiler number for tracking purposes with the Federal Railroad Administration. Gary Bensman photo.

- C&NW 1385’s new wrapper sheet. This will be installed above the firebox. Locations are marked where staybolts will be drilled to secure the wrapper sheet to the firebox. Gary Bensman photo.