The ignition of diesel fuel pushes pistons connected to an electric generator. The resulting electricity powers motors connected to the wheels of the locomotive. A “diesel” internal combustion engine uses the heat generated from the compression of air during the upward cycles of the stroke to ignite the fuel. The inventor Dr. Rudolph Diesel designed this type of engine. It was patented in 1892.

- Diesel fuel is stored in a fuel tank and delivered to the engine by an electric fuel pump. Diesel fuel has become the preferred fuel for railroad locomotive use due to its lower volatility, lower cost, and common availability.

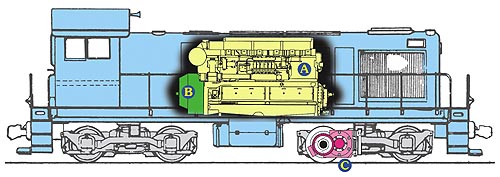

- The diesel engine (A) is the main component of the diesel-electric locomotive. It is an internal combustion engine comprised of several cylinders connected to a common crankshaft. Fuel is ignited by the intense compression, pushing the piston down. The piston’s movement turns a crankshaft.

- The diesel engine is connected to the main generator (B), which converts the engine’s mechanical power to electrical power. The electricity is then distributed to traction motors (C) through circuits established by various switchgear components.

- Because it is always turning, whether the locomotive is moving or not, the main generator’s output is controlled by the excitation field current to its windings.

- The engineer controls the power output of the locomotive by using an electrically-controlled throttle. As it is opened, more fuel is injected into the engine’s cylinders, increasing its mechanical power output. Main generator excitation increases, increasing its electrical output.

- Each traction motor (C) is directly geared to a pair of driving wheels. The use of electricity as the “transmission” for the locomotive is far more reliable than using a mechanical transmission and clutch. Starting a heavy train from a dead stop would burn out a clutch in a brief time.