1385 Update: Grate Progress

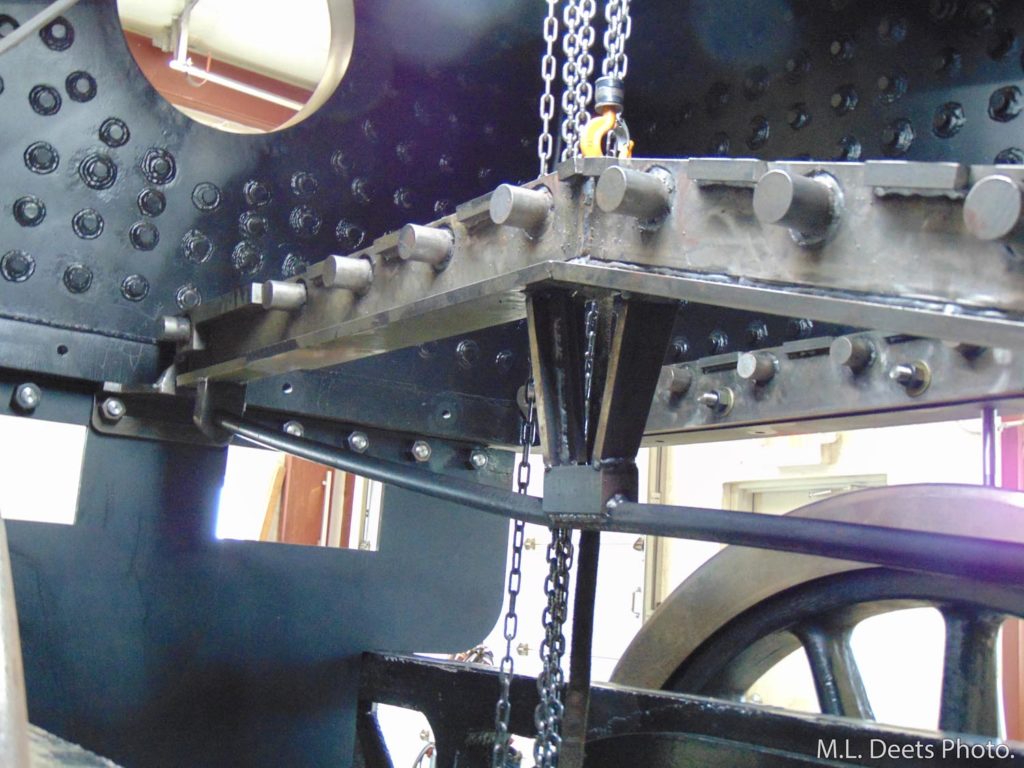

Progress continues on the grate bearers and grates for the #1385. As seen in the following photos, the center bridge has been completed as well as the Engineer and Firemans’ side outside bearers. As will be shown in a moment the grates will be supported by the round pins on the bearers.

With the grate bearers now installed, efforts turned to the grates themselves. Looking from the Fireman’s side (see Grate Photo 1) almost all the grates have been put in place and are hanging from those pins. On the Engineer’s side one grate has been left out (see Grate Photo 2) to illustrate where the grates hang. It can also be seen how the grates pivot or rock on the pins to allow the crew to clean and manage their fire.

Looking in through the firedoor (see Grate Photo 3) at the left side you can see how the grates form a solid yet perforated floor to hold the fuel yet allow enough air up through the fire bed to promote complete & proper combustion. On the right side the grates are rocked forward to a degree that the fireman would be dumping the fire into the ashpan. This is done in the morning while cleaning the fire of yesterday’s ash while preparing for today’s fresh fire and another day of steaming. If the fireman simply needs to even out the fire or shake down some accumulated ash the grates can be rattled back and forth just a small amount. This will cause the ash to fall down into the ashpan through the holes in the grates.

Grate Photo 1: View of grates from underneath the firebox, observed from fireman side.

Grate Photo 2: View of placed grates, observed from engineer side. One grate removed for better view.

Grate Photo 3: View of grates looking through the fire door.

Grate Photo 4: Detail view of grates on engineer side. Some warping is visible.

Grate Photo 5: Large “dump grate” located closest to fire door.

You can see in the photos we are using “experienced” grates. A few are bowed due to poor ashpan management causing excessive heat and causing the grates to warp. Here is a more detailed shot (Grate Photo 4) of the open grates and the large “dump grate” at the bottom of the photo.

The dump grate (Grate Photo 5) is closest to the firedoor and is about the size of two of the other grates. It pivots not in the center but along the edge closest to the firedoor and as the name implies is used to dump a large amount of either ash or fire as needed into the ashpan.

The grates are divided into three sections looking back to front in the firebox and there is the fireman’s set and the engineer’s set. The large tabs that extend down from the bottom of each grate are connected by a series of tie bars, pins and levers to the grate shaker fulcrums in the cab.

At the time the photos were taken, the shaker arrangement was being laid out on the floor for evaluation of the extent of needed repair/replacement of parts. The shaker fulcrums and latches will be mounted to the boiler and some of the other parts will get mounted to the rear boiler support which has also been newly installed.

Bit by bit the puzzle pieces are finding their way back together to form a living, breathing iron horse and soon #1385 will again be the Whistle on the Wind!